MIM parts are often small and intricate, making them ideal for use in electronics, medical devices, aerospace components, automotive parts, and many other industries. MIM products offer several advantages over traditional manufacturing methods, including greater design flexibility, higher strength and durability, and reduced costs.

In summary, metal injection molding is an advanced MIM manufacturing technique that produces small, complex metal parts using a mixture of finely powdered metal and a binder material. This process offers many advantages over traditional manufacturing methods and is widely used in various industries.

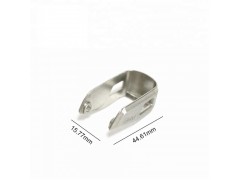

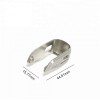

Metal Auto Key Border Protector made by metal Injection Molding